You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mittnz

Red Skull Member

Oh yeah, here’s more on that 4.0L:

So I found it on FB Marketplace for $150, about an hour and a half away from me, in Bumblefuck, CA.

Got it home, asked around if anyone had a cherry picker I could borrow to get it out of the bed of the F-350, and no one did…. I don’t really have a ton of room to store one, so I actually wound up rigging a hoist to the ceiling with that strut channel stuff, and trolley wheels. So, it has full X/Y/Z axis movement, almost like a 3D printer. It ended up working out great, for getting it out of the truck and onto a stand.

I’m still taking it all apart. Need to take the head to a machine shop, but, I’m also considering running an HO head, but keeping the Renix block, and then I can mate it to the HO exhaust headers, and other upgrades that just plain do NOT exist for the 1990…

So I found it on FB Marketplace for $150, about an hour and a half away from me, in Bumblefuck, CA.

Got it home, asked around if anyone had a cherry picker I could borrow to get it out of the bed of the F-350, and no one did…. I don’t really have a ton of room to store one, so I actually wound up rigging a hoist to the ceiling with that strut channel stuff, and trolley wheels. So, it has full X/Y/Z axis movement, almost like a 3D printer. It ended up working out great, for getting it out of the truck and onto a stand.

I’m still taking it all apart. Need to take the head to a machine shop, but, I’m also considering running an HO head, but keeping the Renix block, and then I can mate it to the HO exhaust headers, and other upgrades that just plain do NOT exist for the 1990…

Mittnz

Red Skull Member

Tucked a quick disconnect behind my winch up front, so that I can carry jumper cables with one end quick-connect, they just plug into here. Also, my winch plugs into this port when in use.

The previous owner put this winch on, and one day a few months ago, after it had rained pretty hard, I noticed that the XJ battery was draining to DEAD DEAD, in a matter of hours. Something was just sucking all the life out of it. I did a parasitic draw test with a multimeter, and saw that the winch circuit was drawing a TON of amps, almost like the winch was actively running, but it wasn’t. I assume the solenoid got stuck open.

I bought a cheap Chinese replacement Amazon solenoid, and remote control, and after much “wtf” and looking at Engrish Google Image instruction diagrams, finally got it to work.

Oh also, there have been a couple of times where I had to stop in the middle of a project, drive to Ace and spend $4 on some fuckin nut/bolt that I can’t find anywhere. The last time that happened, I vowed I would never do it again. So, I bought about 100lb of “assorted new Grade 8 bolts and nuts,” as well as some actual, bagged, metric and SAE assortments, and got those organized.

Sitting and sorting nuts and bolts while you’re watching a movie, is a great way to spend Saturday night.

This is also filled with nuts and bolts, sorted.

Springy bois ready to go in with this new front axle.

Attachments

Last edited:

RunningProblem

Red Skull Member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,480

My Jeep changed me. She is wrong. I didn’t know more than a little about cars and now I have the debt to show I learned a little.

This thing looks good. While you’re doing the remix engine rebuild find the injectors to upgrade it. I think the 12 holes are popular. I recall something like a dodge neon being a direct swap but don’t quote me.

Is that the R.E.M. unit from NickInTime in your dash?

I believe the rattle from the door panels would be just the general thin sheet metal wobble sounds. If it’s slightly thicker than 22 gauge it might not wobble. I’m wondering how they’re painted.

Edit: on the ‘changed me’ I’ll say I still hate electrical and now I made the Trail Welder tech article and I couldn’t even weld when I started with my Jeep.

This thing looks good. While you’re doing the remix engine rebuild find the injectors to upgrade it. I think the 12 holes are popular. I recall something like a dodge neon being a direct swap but don’t quote me.

Is that the R.E.M. unit from NickInTime in your dash?

I believe the rattle from the door panels would be just the general thin sheet metal wobble sounds. If it’s slightly thicker than 22 gauge it might not wobble. I’m wondering how they’re painted.

Edit: on the ‘changed me’ I’ll say I still hate electrical and now I made the Trail Welder tech article and I couldn’t even weld when I started with my Jeep.

Last edited:

The Freeak

Pro-Crastinator

What springs did you buy?

Mittnz

Red Skull Member

Yep, managed to score an R.E.M. I love this thing. (I have a few 3D printers, and it’s built on an Arduino, which I have also programmed in the past, I work in IT, so, the NickInTime stuff is right up my alley.)My Jeep changed me. She is wrong. I didn’t know more than a little about cars and now I have the debt to show I learned a little.

This thing looks good. While you’re doing the remix engine rebuild find the injectors to upgrade it. I think the 12 holes are popular. I recall something like a dodge neon being a direct swap but don’t quote me.

Is that the R.E.M. unit from NickInTime in your dash?

I believe the rattle from the door panels would be just the general thin sheet metal wobble sounds. If it’s slightly thicker than 22 gauge it might not wobble. I’m wondering how they’re painted.

Edit: on the ‘changed me’ I’ll say I still hate electrical and now I made the Trail Welder tech article and I couldn’t even weld when I started with my Jeep.

Currently I have the K Suspension 4 hole injectors (not the 12) in the engine in the XJ now, so I will swap those over as well when the time comes. I know the Renix is really picky about injectors, I’m not sure if the gains from 12 hole injectors (vs the current 4 hole) are worth the $$$? I genuinely don’t know.

Mittnz

Red Skull Member

What springs did you buy?

Skyjacker 84-01 Jeep XJ 8in Front Dual Rate Long Travel Coil Springs

Jeep Wrangler JK 2 Door, 7 Inch Front Dual Rate Long Travel Coil Springs, Pair, Dual-rate Long Travel Coils maintain coil in bucket at full droop, Maximizes Articulation, Higher Strength Alloy over competitors prevents sagging, fractures and allows for powder coating in the OEM coils for superb...

jeepandtruckparts.com

jeepandtruckparts.com

Skyjacker 8” XJ Dual Rates. Currently it’s sitting on Rubicon Express 7.5” and I think a 1/2” (or maybe 1”) spacer. I have adjustable coil isolators or whatever they are called, that I want to put on, but those add 1.5” minimum, so, I’d be at 9.5”… idk if that will work.

The only down side to the WJ axle I am swapping in is that it’s low pinion, idk if that will put my drive shaft at too big of an angle?

Mike Honcho

Red Skull Member

I would not even dick with the renix engine. Less power and gremlins in the electrical system. Find a H.O. and swap everything!

Mittnz

Red Skull Member

I know man, I have really been considering this. Especially because most of the performance mods for the 4.0 won’t fit on or work with the Renix. It’s very finnicky about what parts you throw at it, particularly sensors. And the sensors that it does like, are always the most expensive ones of course.I would not even dick with the renix engine. Less power and gremlins in the electrical system. Find a H.O. and swap everything!

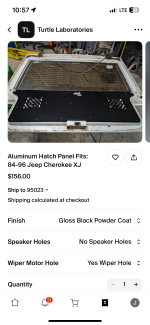

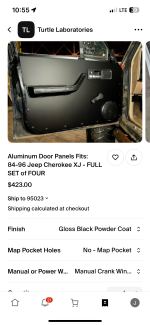

Fuck guys, I bought the aluminum door panels…

I think I’m gonna put the JCR Molle Map Pockets on the fronts, and their rear hatch Molle panel on standoffs, on the rear.

More Molle = more tacticool

Rockwood

An Ape

Sorry, rattle is the wrong word. Make a fuckton of goddamned noise because it's a giant steel sheet. Better?Listing: Aluminum Door Panels - Fits: 84 -96 Jeep XJ Cherokee - Raw Aluminum | eBay

This price is for a set of four (4) door panels.

Require for install:

- Remove factory door cards

- Remove armrest, map pocket from factory door card

- Remove factory door latch handle and assembly

- Reinstall factory components on the aluminum door card

- Reinstall door card with provided 8mm body clips

Door Panel Options:

Finish:

- Raw Aluminum - Though we show images of the panels powder coated, these will be an unfinished aluminum, prepped with heavy burrs removed from the manufacturing process. It is typical for this finish to show some flaws and finger prints. Great if you prefer to coat or wrap them yourself. We also offer them in a powder coat finish, check out our store!

Manual or Power Windows: We can cut the panels to your window configuration.

Map Pocket: We can include holes to install the map pocket, or you may choose to omit them.

Speaker Size: (Speaker holes may need to be modified to fit your particular speaker arrangement, since aftermarket speaker designs widely vary in size. We cut the speaker holes to fit the factory 5.25" speakers. We can also cut them larger if you contact us about custom sizing.

Mounting:

- We provide 8mm body panel clips for install. If mounting holes do not align perfectly, this is intentional. Use a screwdriver, or similar, in any body clip mounting hole to align the hole, while also "preloading" the upper portion of the door panel in the weather strip, in order to prevent vibrating.

Notes: Our speaker holes may need to be modified for your speaker size and/or shape. Since there are so many different speaker configurations, we could not test these panels to be compatible with every speaker in existence. Armrest, door latch, speakers and window cranks not included.

———-

Seems like they just have a bunch of clips where the stock clips are. I don’t know why they’d rattle? You’d still have the door handle and lever screws holding the card to the door, plus the clips all around, plus the speakers holding it tight.

In all seriousness: I assume a decent amount of insulation/backing/dynamat would be a requirement with those. Otherwise, every sound/vibration that hits that door will be reverberated.

RunningProblem

Red Skull Member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,480

The only advantage I can see is his Jeep is currently a Renox so it’s a leg back up motor. Doing a motor swap to the 97+ might be a big deal for a guy like him (or me) with no experience doing it.I would not even dick with the renix engine. Less power and gremlins in the electrical system. Find a H.O. and swap everything!

Mittnz

Red Skull Member

Yeah. This would definitely be my first engine swap, although I have read a ton about what the Renix -> HO move looks like, if I just replaced the harness I could probably make it work, but, definitely seems like it would be a challenge.The only advantage I can see is his Jeep is currently a Renox so it’s a leg back up motor. Doing a motor swap to the 97+ might be a big deal for a guy like him (or me) with no experience doing it.

Also since I am in CA, it has to pass smog, so I can’t do shortcuts like deleting the EGR etc.

Another project I have yet to start, onboard air using my AC compressor. The AC is deleted anyway, and the compressor is just sitting there, so, might as well.

Sorry, rattle is the wrong word. Make a fuckton of goddamned noise because it's a giant steel sheet. Better?

In all seriousness: I assume a decent amount of insulation/backing/dynamat would be a requirement with those. Otherwise, every sound/vibration that hits that door will be reverberated.

That’s a good point, I guess we will find out. I did dynamat the inside of all the door panels, but yeah rolling some of the 50mil that I have onto the back of those aluminum (they aren’t steel! :P) door cards might be a good idea.

Mittnz

Red Skull Member

I was thinking about the same, when I first saw these months ago, and they didn’t used to make them for the first gen XJ’s.I need these in my life. I keep thinking about buying sheet metal to make my own, and they’d end up something like this but way less appealing.

I would think that you could just trace your existing door cards onto a sheet of aluminum, sawzall the rough shape and then die grind the fine parts? I don’t know what alloy they use, but I’m assuming you’d need at least a 4x8 sheet of it, and then you also need a brake big enough to make those bends at the top. Then paint.

$100 a door, powder coated, doesn’t seem THAT bad to me. I’d spend days on one panel and end up fucking it up, it would be crooked and bent to shit, and my 11MPG F350 that I would need to take all the way up to the Metal Supply place in San Jose, would cost more in gas than the metal was worth…

Mittnz

Red Skull Member

Guys talk me off the ledge here, is my 8” lift going to be too much front driveshaft angle with the low pinion D30 WJ axle I am getting ready to swap in?

I’ve been daydreaming at work today about maybe some sort of Frankenswap. I have a HP D30 in the front now, but it has the CAD housing (which I am trying to get rid of). Then I have the WJ LP D30, which I just regeared to 4.56, and cut all of the brackets off of, to weld new, stronger ones on, exactly where they need to go. (WJ spring buckets are like 2” taller, and also 2” closer to the wheels, than the “regular” D30s are).

I’m thinking that since the axle tubes are 2.5” OD, I could just cut the tubes off the WJ diff housing, maybe 3” or so from the housing. Then I could cut the tubes off of the same

Spot on the XJ D30. And then get some 2.75” x 0.125 (so, 2,5”ID) DOM, and essentially create an outer sleeve, then it would be really easy to make sure that I get the length exactly right. (Basically just assemble everything and then weld in place). This would strengthen the axle tubes a ton (both of these axles are inner sleeved already). This would also allow me to keep the WJ brakes, high steering, while still getting to use the cool RCV WJ axles that I have. I would end up with a High Pinion WJ Dana 30. I already have all of the brackets anyway…

I know that if the angle is too extreme, and I have to throw my caster way out of whack to compensate, that I could also just cut and turn the C’s, but, what about the upper control arm mount? It is cast into the housing.

Secondly; I’ve been wanting to get rid of this hitch mount tire carrier since I bought the XJ. I’d put the spare on the roof but these 35’s are heavy as shit, and I am a skinny little IT guy, there’s no way I’d get a tire up there without scratching the shit out of the side of the Jeep, and/or breaking a window in the process. I don’t think my current bumper really has the top surface area to weld a spindle/arm onto it, so I’ve been thinking about other ways.

Anyone seen this? Thoughts? Kratos - The Tire Carrier (WJ, WK, XJ, ZJ)

What’s interesting is that he’s got super strong hatch struts included, that will actually support the weight of a tire on the back. The rest of the parts look pretty simple to fab, and I’m a beast when it comes to Rivnuts, but, my back hatch is fiberglass, so?

I’ve been daydreaming at work today about maybe some sort of Frankenswap. I have a HP D30 in the front now, but it has the CAD housing (which I am trying to get rid of). Then I have the WJ LP D30, which I just regeared to 4.56, and cut all of the brackets off of, to weld new, stronger ones on, exactly where they need to go. (WJ spring buckets are like 2” taller, and also 2” closer to the wheels, than the “regular” D30s are).

I’m thinking that since the axle tubes are 2.5” OD, I could just cut the tubes off the WJ diff housing, maybe 3” or so from the housing. Then I could cut the tubes off of the same

Spot on the XJ D30. And then get some 2.75” x 0.125 (so, 2,5”ID) DOM, and essentially create an outer sleeve, then it would be really easy to make sure that I get the length exactly right. (Basically just assemble everything and then weld in place). This would strengthen the axle tubes a ton (both of these axles are inner sleeved already). This would also allow me to keep the WJ brakes, high steering, while still getting to use the cool RCV WJ axles that I have. I would end up with a High Pinion WJ Dana 30. I already have all of the brackets anyway…

I know that if the angle is too extreme, and I have to throw my caster way out of whack to compensate, that I could also just cut and turn the C’s, but, what about the upper control arm mount? It is cast into the housing.

Secondly; I’ve been wanting to get rid of this hitch mount tire carrier since I bought the XJ. I’d put the spare on the roof but these 35’s are heavy as shit, and I am a skinny little IT guy, there’s no way I’d get a tire up there without scratching the shit out of the side of the Jeep, and/or breaking a window in the process. I don’t think my current bumper really has the top surface area to weld a spindle/arm onto it, so I’ve been thinking about other ways.

Anyone seen this? Thoughts? Kratos - The Tire Carrier (WJ, WK, XJ, ZJ)

What’s interesting is that he’s got super strong hatch struts included, that will actually support the weight of a tire on the back. The rest of the parts look pretty simple to fab, and I’m a beast when it comes to Rivnuts, but, my back hatch is fiberglass, so?

Last edited:

The Freeak

Pro-Crastinator

Let's start with this - Why do you "need" 8" of lift?

Mittnz

Red Skull Member

I don't, but, that's what it was at when I bought it, and so I've just kind of kept it there.Let's start with this - Why do you "need" 8" of lift?

I am on 35's, with cut/folded fenders. Plenty of clearance, no rubbing or anything.

So, it's not so much that I need 8" of lift, as it is that I'd love to just swap this axle in and call it done, rather than having to adjust lift height as well.

The Freeak

Pro-Crastinator

I realize that everyone has a different tolerance for cutting metal, but here is 37's and ~4" of lift.I don't, but, that's what it was at when I bought it, and so I've just kind of kept it there.

I am on 35's, with cut/folded fenders. Plenty of clearance, no rubbing or anything.

So, it's not so much that I need 8" of lift, as it is that I'd love to just swap this axle in and call it done, rather than having to adjust lift height as well.

Also, I'd say that since you have a bit of time and money invested in the WJ front axle, and 8" is going to be tough on the suspension geo and drive line angles -

I'd spend a little on new springs and lower it.

RunningProblem

Red Skull Member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,480

Swap the axle and start saving up for coilovers and one tons.

Mittnz

Red Skull Member

Mittnz

Red Skull Member

I realize that everyone has a different tolerance for cutting metal, but here is 37's and ~4" of lift.

Also, I'd say that since you have a bit of time and money invested in the WJ front axle, and 8" is going to be tough on the suspension geo and drive line angles -

I'd spend a little on new springs and lower it.

I don’t remember if it’s Rusty’s Or DB, but someone makes “rock crawler” fender flares, I think it’s Dirtbound actually, because they are the same as mine but involve more cutting, and they’d be perfect for your rig.

Edit: I was wrong, Rusty’s

Rusty's XJ Front and Rear Crawler High Clearance Steel Fender Flare Package - XJ 4-Door

Rusty's crawler high clearance fender flares are the direct result of customer requests for better, more unique body armor for the XJ Cherokee, and we delivered! Rusty's new XJ Extreme-Clearance Fender Flares are built for hardcore trail use and combine aggressive styling with excellent...

Also they are way higher than I thought.

Mittnz

Red Skull Member

Alright so I spent the whole day doing shit welds on frame stiffeners and haven’t got the new axle underneath yet, tomorrow though!

Mittnz

Red Skull Member

Alright so, I got the bottom and side frame stiffeners on. Finally painted the bump stop “fangs” white (they were red, like the original body color) and I think I got most of the shit tacked on correctly. Definitely helps having the previous XJ D30 to measure. I did tilt the spring perches back a little bit, to avoid bowing. I think the angles on these aren’t quite as critical as the LCA mounts. I have a Johnny Joint for the UCA mount that I need to hammer into the housing still, but, want to paint it first.

I really am trying to figure out all of the angles perfectly, but the more I look at it, since my links are all adjustable, I think I’ll be alright?

It’s dark now, and I’m flying to Disney World this week to meet Rubicon Girl (she’s out there for work, long story) for a few days, so I won’t be able to work on this until next weekend.

I’ll be at Cal4x4’s Molina Ghost Run (at Hollister Hills) 5/10-5/11, if anyone else is going.

Chang805

Member

i don’t know if it was mentioned but just cut and turn the Cs and if that isn’t enough then maybe 8” is too much for the LP

or through the debacle anyone building an XJ go through.

Build up a HP30 or step up to d44. If you go to 44, for the money you can go 60, but lose clearance and the 60 weight is a lot for the unibody long term. Go full frame stiffeners, or fuck just buy something with a frame

or through the debacle anyone building an XJ go through.

Build up a HP30 or step up to d44. If you go to 44, for the money you can go 60, but lose clearance and the 60 weight is a lot for the unibody long term. Go full frame stiffeners, or fuck just buy something with a frame

Mittnz

Red Skull Member

i don’t know if it was mentioned but just cut and turn the Cs and if that isn’t enough then maybe 8” is too much for the LP

or through the debacle anyone building an XJ go through.

Build up a HP30 or step up to d44. If you go to 44, for the money you can go 60, but lose clearance and the 60 weight is a lot for the unibody long term. Go full frame stiffeners, or fuck just buy something with a frame

Considered this. I think rather than cut and turn the C's, I was considering building a frankenswap HP WJ D30.

I have two axles:

An XJ (high pinion) D30, but with the stupid CAD housing, which is like 60.5" WMS to WMS (stock). (CAD has been deleted and replaced with a one-piece axle and a block off plate.)

A low pinion WJ D30, with an Auburn Ecto locker, and RCV Performance RCV axles, in 5x5 bolt pattern, which I want to use. This is WJ width though, ~64" WMS to WMS. It also now has 1/4" heavy(er) duty Artec coil buckets and LCA mounts, as well as an OTK track bar mount, welded (well, currently tacked) on.

Both are geared in 4.56, the HP XJ D30 was in my XJ up until now, and did totally fine with the 8" lift, no vibration or other issues.

Both axles are sleeved, so, I'm thinking that I could just cut the tubes off of both axles (but leave the sleeve intact to use as a truing bar basically) a few inches from the housing, and put the WJ tubes and C's on the XJ D30. This would give me the same axle, but with a HP housing, and the 1/4" diameter sleeves would remain intact, so I know the tubes would be straight.

That's my plan anyway if this lift is too much for the low pinion D30.

Mittnz

Red Skull Member

Aluminum door cards are here.

Have to go play boyfriend for the week so I won’t be able to put them in until this weekend :(

They look nice though! I’ll do a more thorough review when I install them. At first glance though, they definitely will need some sound deadening rolled on the backs…

RunningProblem

Red Skull Member

- Joined

- Sep 12, 2020

- Member Number

- 2860

- Messages

- 2,480

Dana 60s and full frame stiffeners makes adding tube a lot easier. Plus with built one tons you can scrap the unibody and swap them over to something else.i don’t know if it was mentioned but just cut and turn the Cs and if that isn’t enough then maybe 8” is too much for the LP

or through the debacle anyone building an XJ go through.

Build up a HP30 or step up to d44. If you go to 44, for the money you can go 60, but lose clearance and the 60 weight is a lot for the unibody long term. Go full frame stiffeners, or fuck just buy something with a frame

Rockwood

An Ape

Gas tank in stock location, or moved into the trunk?I realize that everyone has a different tolerance for cutting metal, but here is 37's and ~4" of lift.

Also, I'd say that since you have a bit of time and money invested in the WJ front axle, and 8" is going to be tough on the suspension geo and drive line angles -

I'd spend a little on new springs and lower it.

If the vibes are bad, I'd just lower it. At 8", everything gets wonky. Hell, at 5" lift (where I'm currently at), steering/track bar angles aren't the best, and caster is a tradeoff between stability and vibration (solved by cut/turn though).Considered this. I think rather than cut and turn the C's, I was considering building a frankenswap HP WJ D30.

I have two axles:

An XJ (high pinion) D30, but with the stupid CAD housing, which is like 60.5" WMS to WMS (stock). (CAD has been deleted and replaced with a one-piece axle and a block off plate.)

A low pinion WJ D30, with an Auburn Ecto locker, and RCV Performance RCV axles, in 5x5 bolt pattern, which I want to use. This is WJ width though, ~64" WMS to WMS. It also now has 1/4" heavy(er) duty Artec coil buckets and LCA mounts, as well as an OTK track bar mount, welded (well, currently tacked) on.

Both are geared in 4.56, the HP XJ D30 was in my XJ up until now, and did totally fine with the 8" lift, no vibration or other issues.

Both axles are sleeved, so, I'm thinking that I could just cut the tubes off of both axles (but leave the sleeve intact to use as a truing bar basically) a few inches from the housing, and put the WJ tubes and C's on the XJ D30. This would give me the same axle, but with a HP housing, and the 1/4" diameter sleeves would remain intact, so I know the tubes would be straight.

That's my plan anyway if this lift is too much for the low pinion D30.

Chang805

Member

Good point, you could reuse pretty much everything besides the body on another build. Also a lot of people wont wheel it enough to get to the point where the unibody is not usable anymore.Dana 60s and full frame stiffeners makes adding tube a lot easier. Plus with built one tons you can scrap the unibody and swap them over to something else.

For me personally though, I will probably keep my XJ as is on stock axles and 3 inch lift. I want to start off with a different platform to put big stuff on,

filthy_midget

Member

- Joined

- Apr 25, 2024

- Member Number

- 7748

- Messages

- 14

lmao nice. Just be wary if you find a chick that likes wheeling. You think forgetting to take out the trash is bad just wait until the jeeps down and the wife and kids want to go out. "Why are you in the house!! Go back to the garage and get the jeep going!!" LolPart of the transcript from the last 2-minute long rant voicemail she left me:

Now I have way more money, time to myself, and a sick XJ. Just need to burn some sage in the front seat to get rid of that negative energy. Trust me, this was a win!

Mittnz

Red Skull Member

So far, I have just been running it the way that it was given to me.Gas tank in stock location, or moved into the trunk?

If the vibes are bad, I'd just lower it. At 8", everything gets wonky. Hell, at 5" lift (where I'm currently at), steering/track bar angles aren't the best, and caster is a tradeoff between stability and vibration (solved by cut/turn though).

I had some gnarly death wobble after I pulled the steering dampener/stabilizer off (while I was trying to get the locker in the front) and forgot to put it back on. The main cause was that the Pittman arm was kind of blown out and then the threads on the sector shaft were stripped so the nut wouldn’t tighten all the way. This caused a bad dead zone in the middle of the steering. On the way out that day (took it to Clear Creek BLM land) I was having to steer like 1/4 turn in each direction just to make minor steering corrections driving down the road. Then without that steering stabilizer, it just all went to shit, and any time I hit even the smallest bump, going more than about 10mph, while turning, I got death wobble and couldn’t do anything but brake and hope the front end didn’t just shake itself apart.

I ended up replacing the entire steering box, and tightened everything up and it has been fine ever since. Although, I don’t really have anything to compare it to, since it’s my first Jeep.

I guess my point is that with the 3-link adjustable long arms, Johnny joints, steering stabilizer, a drop pitman, and “one ton steering”, it has actually done great with the 8-inch lift. I’ve never had any drive shaft vibes either. (I have Adam’s drive shafts front and rear)

I also bought half the stuff I need to 4-link the rear, a few weeks ago. (A truss with the 4-link setup, and the IRO XJ 4-link crossmember. I will probably just fab the links myself, haven’t decided yet.). I haven’t bought rear coil springs yet, so, I’m trying to plan this out a little better than I have previously, and coordinate.

Here are some pics of my steering setup and geometry as I got it from the previous owner (so, before I pulled this axle out to swap in the WJ axle) and it was doing well at 8”:

I swapped his previous stabilizer for the Rusty’s one, but otherwise this is how I got it. (The welds look even worse than mine, and that truss is a little butchered, but that truss also wasn’t made for the CAD axle)

Last edited: